On July 15th, the "Manufacturing Enterprise Digital Transformation Theory and Practice Seminar" was successfully held at South China University of Technology. This seminar is organized by the Guangzhou Federation of Social Sciences and hosted by South China University of Technology. This seminar was presided over by Zhang Zhengang, a second level professor and doctoral supervisor at South China University of Technology, and director of Guangzhou Digital Innovation Research Center. Vice President Li Weiqing of South China University of Technology and full-time Vice Chairman Guo Deyan of Guangzhou Federation of Social Sciences attended and delivered speeches.

Due to the need for epidemic prevention, the seminar adopts a combination of online and offline forms, with over 500 representatives participating both online and offline. Mr. Zhang Chengkang, Chairman and CEO of SiE Information, was invited to participate in an online sharing titled "Practical Exploration of SiE Information Empowering Digital Transformation in Manufacturing Enterprises". Experts, scholars, and business representatives from Zhejiang University, Central South University, Northeastern University, and Baiyun Electric Group also discussed and shared their exploration and thinking on digital transformation in the manufacturing industry from different perspectives such as cognition, innovation, philosophy, and data empowerment.

User thinking is important

In the future, the digital assets of enterprises will become increasingly important, but when it comes to digital transformation of enterprises, it is necessary to learn user thinking, "Chairman Zhang Chengkang emphasized in the theme sharing.

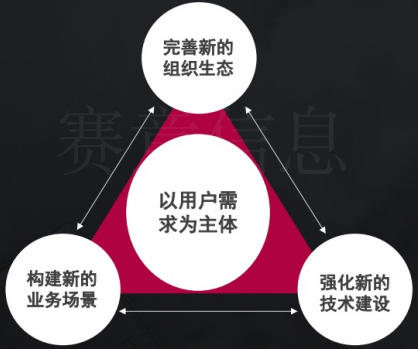

The digital transformation of enterprises is not simply a technological transformation or on-site improvement, but a comprehensive transformation and upgrading covering various aspects of enterprise strategy, management, organization, operation, etc. He pointed out that in the past, manufacturing enterprises usually hoped that using a set of OA and ERP systems could solve all process efficiency problems and achieve productivity improvement and cost reduction. However, modern manufacturing enterprises face differentiation in various aspects such as operation management, production processes, manufacturing processes, warehousing and transportation, and more importantly, need to tailor according to actual user needs. SiE Information adheres to the "One Body Three Wings" strategy, which focuses on user needs, strengthens new technology construction, constructs new business scenarios, and improves the new organizational ecology as the three wings, and constructs the digital transformation direction of the enterprise with technological innovation and user thinking.

Managers' transformational thinking is the first step in enterprise transformation

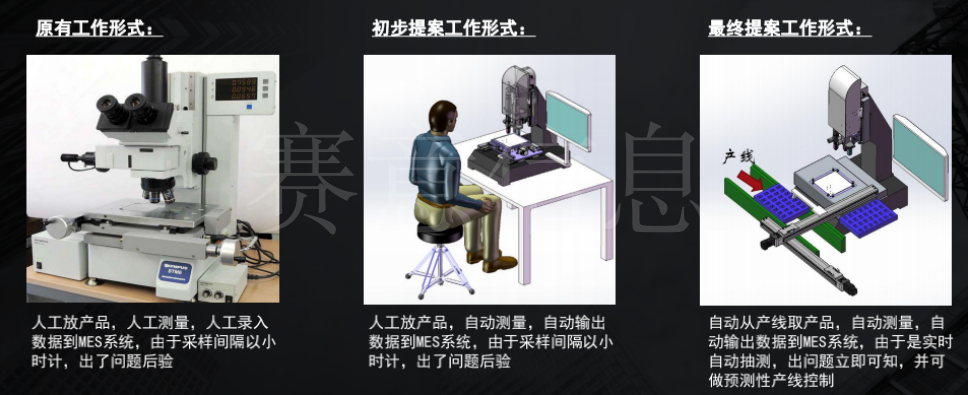

At present, the digital transformation of China's manufacturing industry is accelerating. According to research data, it is estimated that digital transformation can bring an 8% to 13% increase in profits for manufacturing enterprises. Chairman Zhang Chengkang mentioned, "Especially when the cost of digitization is getting lower and labor costs are getting higher, and this intersection is forming a cost" scissors gap ", digital transformation will become an inevitable choice for enterprises Taking the transformation from manual detection to automatic detection using machine vision as an example, SiE Information has developed a digital transformation solution for a certain electronic component enterprise based on enterprise specific conditions. By replacing manual quality detection with visual AI alone, not only errors are reduced, but efficiency is also greatly improved. Calculating from labor and training costs, the cost can be recovered within two years, achieving true staff reduction and efficiency increase.

However, many companies may hesitate to implement digital transformation due to excessive initial investment. Therefore, the digital transformation of enterprises requires managers to first transform their management thinking.

Deepening into the industry to become more competitive

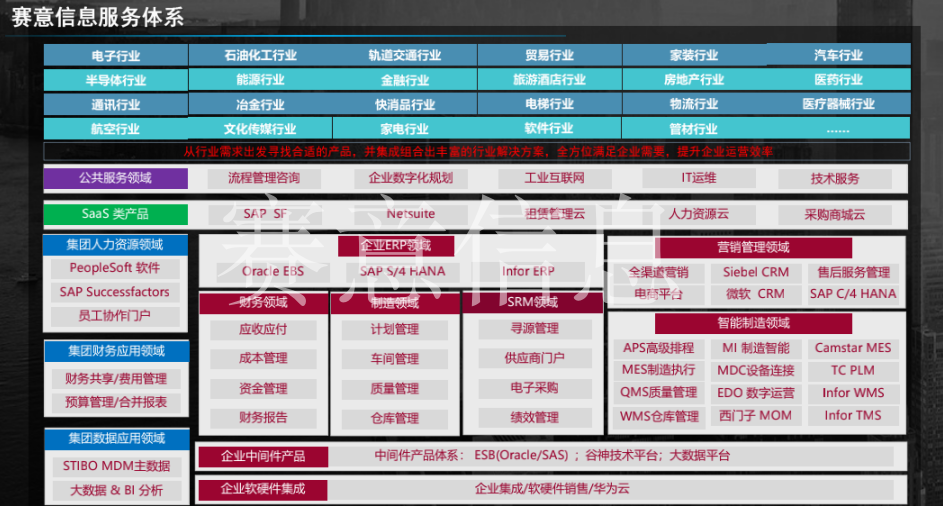

Industrial software, as an important foundation and core support for intelligent manufacturing, is of great significance in promoting the transformation and upgrading of China's manufacturing industry. SiE Information believes that in the process of empowering customers to transform, software companies not only have strong technical product capabilities, but also ultimately compete for industry awareness and understanding of user scenarios, that is, the ability to provide a set of consulting and solutions suitable for local enterprise needs, and break through the "pain points" of customer transformation.

As a leading industrial management software enterprise in China, SiE Information has been deeply involved in various industries since its establishment for 16 years. It has been deeply understanding the implementation, application, and latest exploration of various different needs in the developing manufacturing industry, helping enterprises of all sizes and industries to manage the research and development, manufacturing, marketing, and operation of the entire enterprise in a digital manner. We provide products and solution packages for 23 industries and 11 business lines, including electronic semiconductors, home appliances, and mechanical equipment. We have successfully implemented and received recognition and praise in over 1000 industry benchmark customer enterprises such as Huawei, Midea, Ping An, vivo, Oupai Home, and Dajiang.

2021 is the first year of China's "14th Five Year Plan" to embark on a new journey of comprehensively building a socialist modernized country. How to seize the opportunity to help enterprises take advantage of the development trend of the "14th Five Year Plan", build a path for future digital development of enterprises, and make contributions to supporting the country in completing the "14th Five Year Plan" is an important topic for industry experts and enterprise leaders. As a digital empowerer for enterprises, 90% of SiE Information's customers come from the manufacturing industry. In the future, we will continue to delve into the upgrading of the manufacturing industry, assist Chinese enterprises in continuously improving their digitalization and intelligence levels, and assist manufacturing enterprises in gear shifting and upgrading.