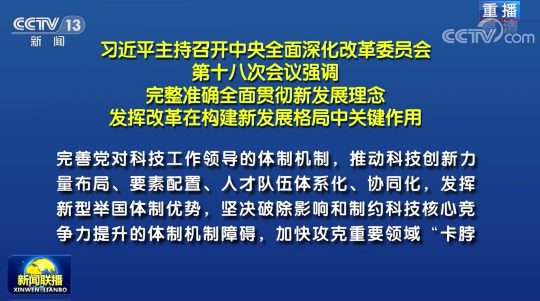

On February 19, 2021, the 18th meeting of the Central Commission for Deep Reform emphasized the need to leverage the advantages of the new national system and accelerate the capture of "bottleneck" technologies in important fields. Industrial software, which is related to independent and controllable industries, has become one of the key areas under the new development pattern.

Industrial software integrates the experience of enterprises in core processes such as product planning, design, management, and sales into a software system. Essentially, it optimizes the manufacturing process and improves the work efficiency of the entire process through the commercialization of industrial knowledge. It is the core of intelligent manufacturing.

As the engine of the "digital economy", the proposal on industrial software has also become a hot topic of attention at the just concluded two sessions:

-On the basis of unified data standards, we aim to cultivate core industrial software enterprises and create an industrial software system with an integrated and open architecture for product comprehensive optimization and full lifecycle requirements;

——Wang Yongtian, member of the National Committee of the Chinese People's Political Consultative Conference and professor at the School of Optoelectronics at Beijing University of Technology

-We need to strengthen top-level design and promote the localization of industrial software from a national strategic perspective.

——Xu Xiaolan, member of the National Committee of the Chinese People's Political Consultative Conference and president of the China Industrial Internet Research Institute

-At present, the core technology of industrial software in China cannot achieve self-control, and the lack of independent industrial software is highly likely to lead to the loss of initiative in industrial development. Suggest accelerating the development of industrial software and consolidating the foundation for high-quality development of the manufacturing industry;

——Qian Feng, Chairman of the Jiusan Society in Shanghai and Vice President of East China University of Science and Technology

-Focusing on key core technologies such as industrial software and hardware, industrial operating systems, and high-end equipment, we will leverage the advantages of the new national system and strengthen our efforts to tackle key issues through mechanisms such as application traction, overall drive, and leadership. Increase the application of domestically produced software and hardware, innovate systems such as "insurance compensation+alternative catalogs", encourage state-owned assets and key areas to prioritize deployment and application, and accelerate the iteration of domestic product updates.

——Zhang Ying, member of the National Committee of the Chinese People's Political Consultative Conference and Deputy Director of the Shanghai Municipal Commission of Economy and Information Technology

-Increase support for the industrial software industry, establish industry support funds, fully support mature and commercialized software products and enterprises, and provide tax incentives.

——Mo Changying, Member of the Standing Committee of the National Committee of the Chinese People's Political Consultative Conference and Chairman of the Guangxi Zhuang Autonomous Region Federation of Industry and Commerce

The industrial software system is divided into three parts: industrial design software, industrial control software, and industrial management software. These three parts are not only the upstream and downstream relationships in the field of digital transformation, but also the symbiotic closed-loop relationship. The development of the three parts promotes and restricts each other.

The biggest problem encountered in the fields of industrial design software and industrial control software is being "choked", while the field of industrial management software is undergoing an "arms race".

Industrial management software integrates big data, artificial intelligence, and industrial scenarios, and has evolved from the past management informatization to an important lever for the transformation of the manufacturing industry to service-oriented, forming a certain competitive advantage. This is also a magic weapon for the domestic manufacturing industry to achieve transformation and leadership.

SiE Information, a domestic industrial management software practitioner, has been focusing on and serving key industry areas for 16 years, especially in the early stage of digital consultation and the provision and application of solutions in the industrial manufacturing industry. In this process, rich digital experience in application scenarios has been accumulated and precipitated. At the same time, a complete set of industrial management software has been independently developed through "imitation before innovation", such as SRM (Supplier Relationship Management), Production Planning and Scheduling (SAPS), Manufacturing Process Management (SMES), Warehouse Management (SWMS), Quality Management (SQMS), Equipment Operations Management (SEDO), Equipment Integration (SMDC), Digital Intelligent Operations (SMI), and other core industrial management software required for manufacturing management.

SiE Information Industrial Management Software has strong integration and natural "localization" attributes, and can be customized according to the actual application needs of enterprises. It has strong scalability and is highly compatible with the actual production scenarios of local enterprises. It has become an industry recognized "high-quality and cost-effective" localization "industrial management software, and has been applied in the top central customers in China and has been recognized and praised.

At the same time, based on the industry attributes of customer enterprises, SiE Information has developed industry-specific industrial management software packages for key industries such as communication electronics, PCB semiconductor, and pan home furnishing, forming a business model of "standard platform+industry package+configuration services".